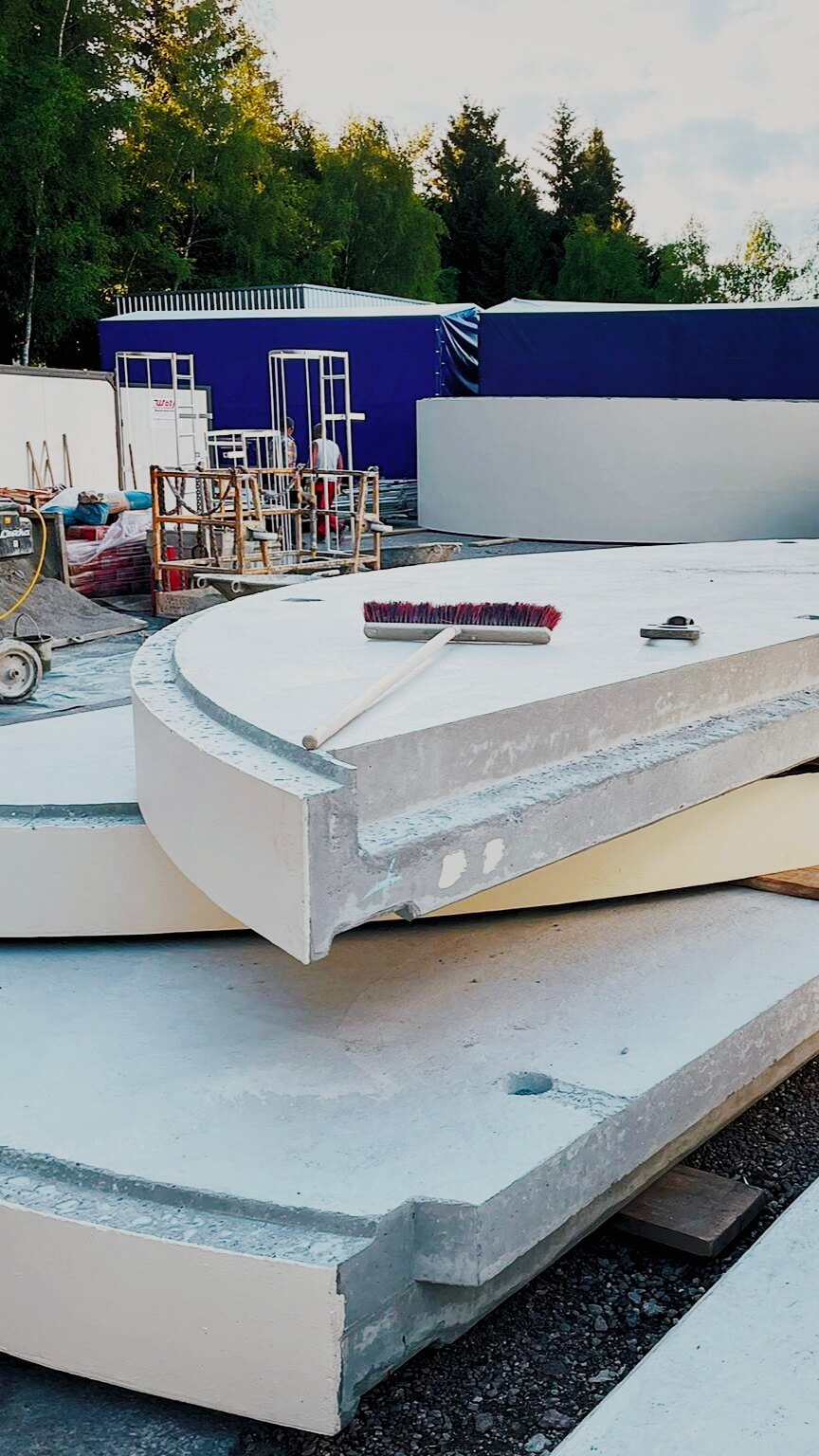

Chip silo in place. Heating system to follow!

When we first started thinking about a more efficient heating system at the beginning of this year, it quickly became clear that this investment would also entail building modifications.

Trigger for the investment

An overall increase in heat demand, especially at the beginning of the day, was forcing our old system to its knees. In addition, the environmental aspect naturally also played a driving role. With a modern heating system, we wanted to make our contribution and further reduce our emission levels.

So one thing led to another

Instead of a new, larger boiler room, we built a 19.1 metre high chip silo last week! In the lower area, it provides space for our new heating system. Next to it, a 25,000-litre water tank ensures continuous operation of the entire system. In future, this will act as a buffer to compensate for peak demand at the start of work.

The advantages are obvious

Compared to our old storage facility, we can store twice the volume in the new chip silo. This means that we can fill our silo in summer and burn the chips in winter. There is no need to transport the chips away in summer and buy heating material in winter. We are therefore able to cover our entire fuel requirements ourselves. In addition, we reduce our emission values and benefit from a higher efficiency of the plant.

The heating system will be built at the end of the year. But already now we fill the silo and collect the heating material for the coming winter!