Strikingly profiled solid wood table legs

3D-milling in contract work

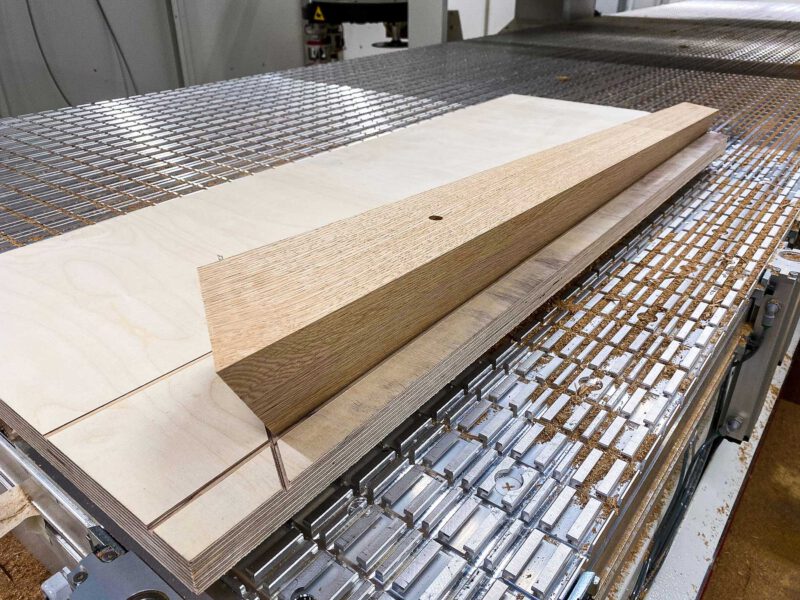

The substructure of the sophisticated dining table consists of three strikingly profiled solid wood parts, which are connected tangentially to each other. Together with the table top, this results in a very aesthetic connection that almost resembles a sculpture.

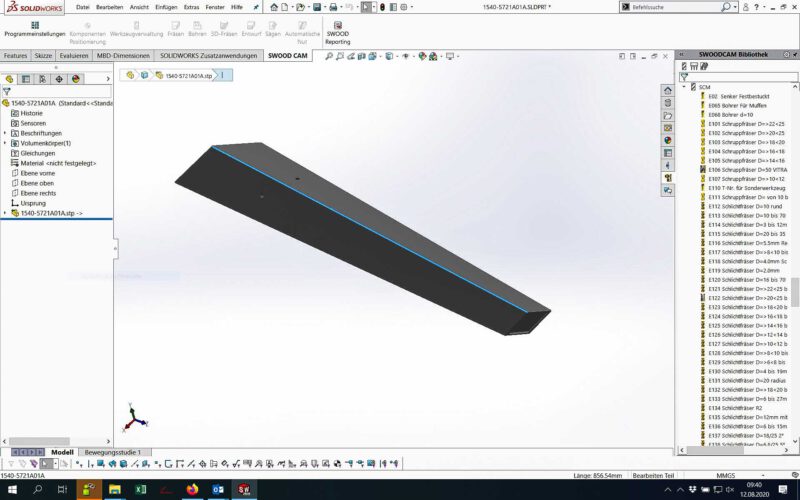

Whenever our human imagination feels almost tricked, our technology comes into play. We take over the data with our volume-based 3D-CAD system, prepare it and pass it on to the production department. The high degree of complexity is perfect for our new 5-axis processing machine. Here we manufacture the table legs in one clamping using vacuum clamping technology. Very economical, fast and of course with high machining accuracy!

We support our customer in the production, take over hand in hand the complete processing of the base frame and deliver the raw sanded scantlings in the solid wood types oak and American walnut for further processing there!